Below you will find information about the sanding belts, abrasives and backing.

Types of abrasives:

Ceramic

Ceramic abrasive belts are the ones that do the most work. They remove a lot of material quickly and last a long time, in fact up to 6 times longer than aluminum oxide. The ceramic grains are crushed as you grind, so you always have sharp grains ready. Combat abrasives' Shredder ceramic also contains "Grinding Aid" which reduces heat generation and extends the life of the belt.

Well suited for:

- Sanding most materials, but especially steel. New, unused belts are very effective on wood and plastic.

- Removal of large amounts of material

- Profile grinding of steel parts/preparation for welding

- When you don't want to change belts so often :)

Aluminum Oxide (Aluminum Oxide, AO)

Aluminum oxide has many uses, but is, due to its hardness, widely used in abrasive products. The belt contains abrasive in the form of aluminum oxide crystals. AO also boasts low heat capacity and low production cost. Together, this results in solid abrasive belts that cut well and are inexpensive. Comes with different backings with varying strengths, e.g. J-flex and X-weight (see description below).

Well suited for:

- Most materials including wood, composite, steel and other metals

- General use in coarse grinding

- Detail work in finer grit, e.g. 400 grit for sharpening knife edges

Cork (Cork Polishing)

Cork belts, as the name suggests, are belts with cork grains. These grains are impregnated with silicon carbides. Silicon carbide is on par with diamond in hardness, and the mixture of cork and fine-grained silicon carbide gives a beautiful satin finish.

Well suited for:

- Used, for example, after fine grinding with AO belts, and gives a nice homogeneous finish

- Often used as the final finishing touch during the sanding phase

Belt backing:

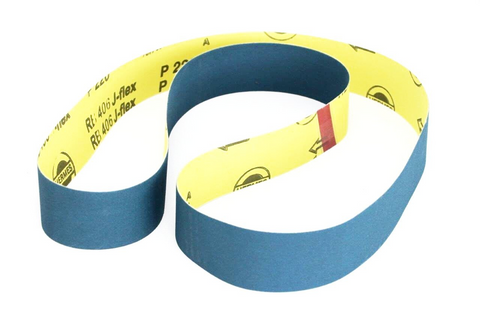

J-flex

The softer, more flexible belts are called J-flex. They have a lighter backing that allows them to better follow the contours of the product being sanded. Works well for smoothing out sharp edges and corners.

X-weight

Stiffer belts with harder backing fall into the X-weight category. These still yield to pressure but offer more resistance than J-flex. Used for general sanding with AO belts.

Storbua.no and www.eternalknives.com use Combat Abrasives. They do the job best, which is why we have chosen to stock belts from Combat Abrasives:

See our selection by clicking on the logo.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.